History around every corner…

“Unless a man understands the Weald, he cannot write about the beginnings of England.” Hilaire Belloc

For over a thousand years, people have shaped the natural beauty of the High Weald.

It is a medieval landscape of wooded, rolling hills; studded with sandstone outcrops and a rich patchwork of small fields, scattered farmsteads and ancient routeways.

Situated in the heart of rural South East England, the High Weald National Landscape covers 1,461 square kilometres across the counties of Kent, Sussex and Surrey. It is the fourth-largest National Landscape in England and Wales, and without doubt one of the most beautiful.

The High Weald is a very special place. And it’s all yours to discover.

PLEASE NOTE: In November 2023, all AONBs were renamed as National Landscapes. This change was recommended by the Government’s Landscapes Review in 2019.

The High Weald National Landscape remains designated as an Area of Outstanding Natural Beauty (AONB) and is referred to as such in policy, legislation and guidance.

97%

enjoy the High Weald countryside. High Weald Public Engagement Survey, 2018

Protecting the landscape for future generations

As a designated Area of Outstanding Natural Beauty (AONB), the High Weald is protected by law to conserve and enhance its natural beauty.

There are 46 AONBs in Britain, part of a family of protected landscapes that include National Parks and Heritage Coasts.

AONBs are designated by Government to ensure that the conservation and enhancement of the landscape is given high priority.

The High Weald was designated as an AONB in 1983.

The High Weald in numbers…

- 3,720 species of plants and animals

- 12,500 km of hedgerows and field boundaries

- Over 13,000 ponds with native wildlife

- 28% woodland cover – more than any other AONB

- 20% of all lowland meadow in England

- 227 km2 sites of biodiversity value

- 2,570 km of public rights of way

- 127,000 inhabitants

- Over 1 million people living within 5 km of the boundary

- 100 parishes

- 17 market towns and larger villages

- 3,500 historic farmsteads

- 30 manor houses, castles & gardens.

Discover what makes the High Weald Outstanding

Every landscape has a story and the High Weald is no exception.

It’s natural beauty comprises eight defining ‘character components’ that have made it a recognisably distinct and homogenous area for the last 700 years. Each of these has its own dedicated section of the High Weald AONB Management Plan.

The High Weald is also treasured for its rich history, diverse wildlife and fascinating archaeology.

Scroll down to start your journey through this precious and breathtaking landscape…

Natural Systems (Geology, Soils, Water and Climate)

A deeply incised, ridged and faulted landform of clays and sandstone. The ridges tend east-west, and from them spring numerous gill streams that form the headwaters of rivers. Wide river valleys dominate the eastern part of the landscape.

Settlement

The High Weald has many isolated farmsteads, hamlets and dwellings dotted across the countryside. Picturesque ridge-top villages enjoy soaring views, and historic farmsteads nestle in sheltered valleys. This characteristic, dispersed settlement pattern, actually supports the highest population of any protected landscape in the UK.

Routeways

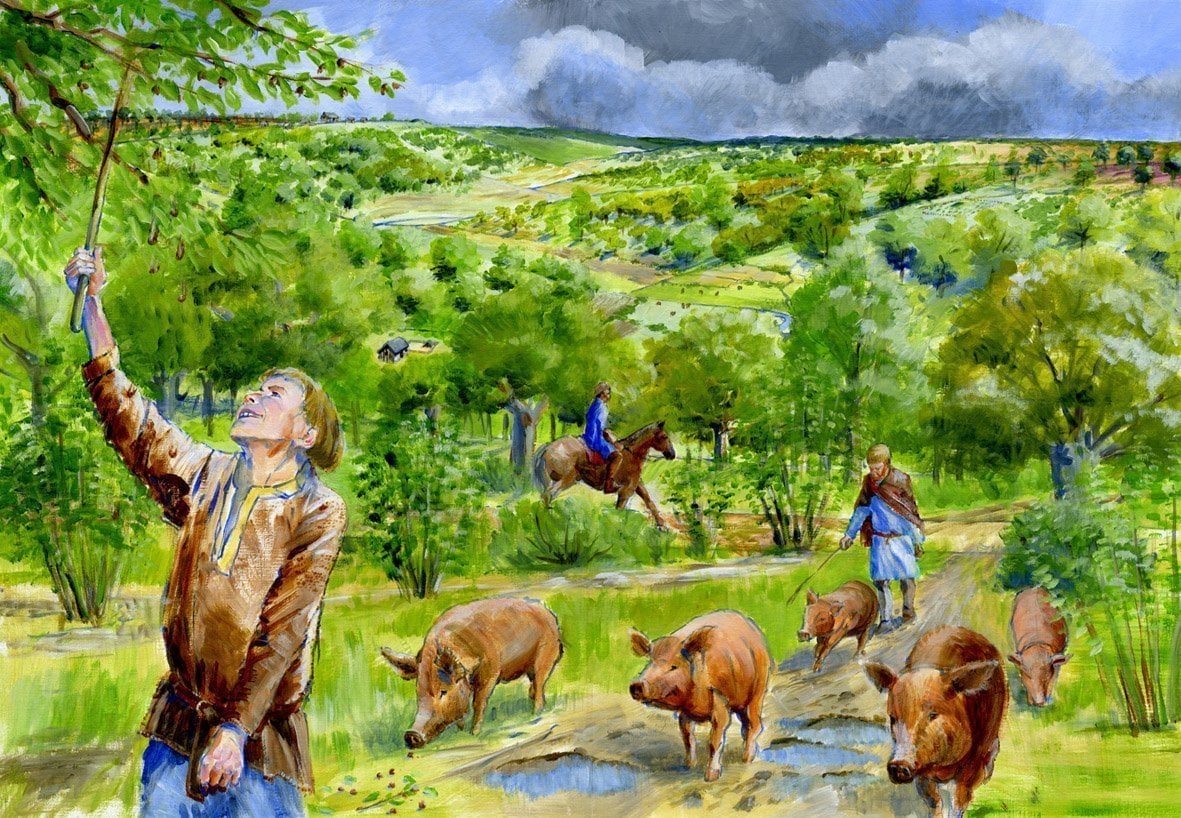

The High Weald is characterised by a network historic and atmospheric routeways (now roads, tracks and paths), the oldest being in the form of ridge-top roads and a dense system of radiating droveways. These are often narrow, deeply sunken and edged with wildlife-rich trees, hedges, wildflower-rich verges and boundary banks.

Woodland

The word ‘weald’ comes from an old word meaning ‘wood’ related to the German word ‘Wald’. Trees and woodland are a particularly distinctive feature of the High Weald landscape, covering nearly a third of the AONB – much of it being precious ancient woodland. A crucial source of shelter, food and power for early settlers and a haven for rare wildlife, today this valuable habitat stores 7.5 m tonnes of carbon with more sequestered every year.

Fieldscapes and Heath

The High Weald’s rolling hills are draped with small, irregular fields – edged with ancient boundaries such as hedgerows and tree belts, and often containing nationally-important species-rich grassland. Colourful areas of heath – with patches of purple heather and yellow gorse – are found on the high, sandy ridges, most famously on the Ashdown Forest. This pattern of small, irregular fields grew out of the way the High Weald was settled, and is the result of the patient work of many small farmers.

Dark Skies

The High Weald is characterised by having some of the darkest skies in the south-east of England, with the least skyglow. This contributes to the sense of remoteness and peacefulness of the AONB. Key constellations such as Orion and Ursa Major are visible to the naked eye. Additionally, a number of nocturnal species within the High Weald are dependent on dark skies for feeding.

Aesthetic and Perceptual Qualities

These are sense-based qualities, experienced as a result of people’s interaction with natural beauty and their immersion in it, within the High Weald’s landscape. They include the sense of history and timelessness arising from an ancient countryside, the appreciation of the quintessential pastoral landscape, a rich and varied biodiversity, the colour palette of the landscape, tranquillity, and the legacy of features and ideas left by writers, artists, and gardeners inspired by the landscape.

Land-based Economy and Rural Living

The High Weald has a significant land-based economy and related rural community life, focussed on mixed farming (particularly family farms and smaller holdings), woodland management and rural crafts.

Other important aspects of the High Weald

History

The High Weald lies within one of the largest tracts of woodland remaining in early Medieval England. The Weald is one of the longest-lasting regional names in Britain. Termed Anderida silva by the Romans, and later as Andredsweld (the high forest of Andred), the area’s name was shortened to Weald in saxon charters. It was sometimes associated with weald-bera or den-bera – the right to feed swine in the forest.

Wildlife

The High Weald’s diverse mix of interconnected habitats – many unchanged since medieval times – is home to an astonishing range of flora and fauna, which add to the unique character of the area…

Archaeology

The archaeology of the Kent, Sussex and Surrey High Weald tells us a lot about past use of the landscape. In particular, the area’s ancient woodlands hold many secrets – they have seen less change compared to agricultural land, and the archaeological features within them are often well-preserved and still waiting to be discovered…

How is the High Weald AONB managed?

The High Weald AONB Management Plan sets out the long term objectives for conserving this treasured landscape and how it will be looked after for the next 5 years.

It sets the benchmark for AONB conservation, as well as guiding residents, businesses and visitors on what they can do to help safeguard this special area.